Globally Backed, Locally Driven

Innovation is a cornerstone of our growth strategy. Leveraging the global presence and brand strength of the Tenneco Group, we bring advanced technologies and global best practices to the Indian market.

Our R&D efforts are driven by close collaboration—with both our customers and global partners—ensuring reliable and market-ready solutions. With a strong foundation in research, design, and engineering, we are committed to delivering innovation that empowers progress for our customers and communities.

Pioneering Emission Control

In 2014, we deployed SCR converter technology for BS4-compliant CVs in India. We continued this momentum with advanced solutions for BS6 and BS6.2 standards, including LNT, SDPF, DPF, and gasoline particulate filters.

Our next-gen SCR systems support real-world driving conditions, and we’re now developing future-ready technologies like e-heaters and hydrogen fuel-compliant systems.

Trailblazing Global Innovation

We launched the multi-tune valve technology in India in Fiscal 2012, after which it was validated and introduced to the market in other regions. We launched the design of the strut and shock in the market in India in Fiscal 2015 using a piston rod and piston of smaller diameters while maintaining the same performance level of ride quality.

Most recently, in fiscal 2024, we brought to market an advanced hydraulic rebound system which is used in the Mahindra Thar Roxx, before its commercialization in other regions by the Tenneco Group. We are exploring the rollout of next-generation double tube construction valves in India, which enhance ride comfort by providing better control of hydraulic rebound and compression, in calendar year 2025.

End-to-End Design Solutions

We partner with customers to provide end-to-end design solutions, including tool and die manufacturing, engineering solutions, new system and component design, enhancements to existing systems and components, benchmarking, design analysis and simulation, rapid prototyping, testing and validation, lightweighting, process optimization and material optimization.

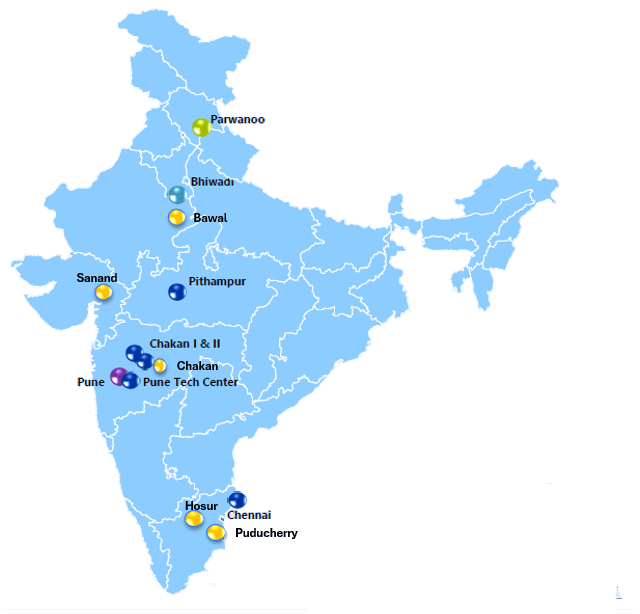

Our Research and Development Centers

Clean Air and Powertrain Solutions Tech Center

Chakan Plant | Pune, Maharashtra

- Functional simulations based on customer inputs or benchmark data, such as CFD

- Engages in product testing through its four test cells

- Equipped for validation testing: hot shaker, bending fatigue, weld fatigue, thermal shock, thermal cycle, and vibration testing

- Post-test analysis capabilities: weld seam analysis and material composition analysis

Advanced Ride Technologies Tech Center

Hosur | Tamil Nadu

- Prototyping, testing and validation for performance, reliability and durability

- Mobile labs for fine-tuning ride and handling on test tracks